Aircraft rely on a wide range of electric motors and actuators, from landing lights and windshield wipers to air circulation systems. Over time, these components face wear and tear, affecting performance and operational efficiency. Investing in professional aircraft motor repair solutions can be a game-changer, offering both reliability and cost savings while extending the lifespan of critical parts.

Here’s how expert motor repair solutions make a difference:

1. Thorough Diagnostics and Testing: Advanced inspections identify potential issues early, preventing costly failures before they occur.

2. Precision Repairs: Components are repaired to meet exact OEM and regulatory standards, restoring full functionality.

3. Quality Part Replacement: Consumable parts are replaced with high-quality alternatives, ensuring extended durability.

4. FAA/EASA Compliance: Repairs adhere to strict aviation standards, giving operators confidence in component reliability.

5. Cost-Effective Maintenance: By repairing rather than replacing motors, operators save thousands while maintaining peak performance.

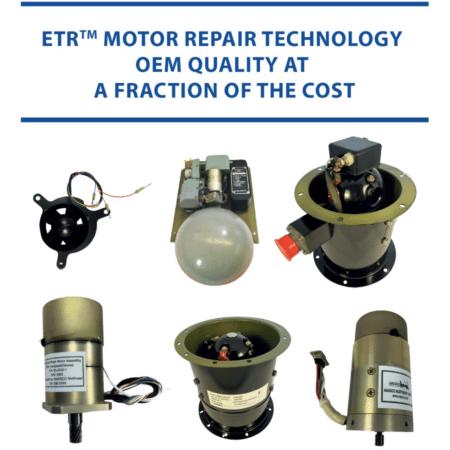

6. Versatility Across Components: Solutions cover AC/DC motors, actuators, fans, micropumps, and more, supporting a wide range of aircraft systems.

Extending the life of aircraft components is not just about saving money, it’s about keeping aircraft safe, reliable, and ready for the skies. A strategic approach to motor repair ensures each component operates at optimal levels for longer periods, minimizing downtime and maximizing fleet efficiency.

For proven, cost-effective, and FAA/EASA-approved aircraft motor repair solutions, trust NAASCO. Submit your RFQ today!

Write a comment ...