Aircraft electrical generator are crucial for powering vital systems during flight. From lights to communication tools, everything depends on consistent electrical output. Like all mechanical parts, generators can wear out over time. And when they do, the entire electrical system could be at risk.

Recognizing early warning signs can help prevent expensive repairs and safety issues. Besides, timely maintenance can extend the life of your generator. This blog will highlight six common signs that your aircraft’s electrical generator may need repair or replacement.

Warning Signs of a Failing Aircraft Electrical Generator

Aircraft generators rarely fail without warning. Most show signs before a complete breakdown occurs. Knowing what to look for can save time and money. Below are the six key signs that indicate your generator may require immediate attention.

1. Unusual Noises During Operation

Strange or loud noises should never be ignored. If you hear grinding, whining, or rattling sounds, something could be wrong inside the aircraft generator. These noises often come from worn-out bearings or loose components. What's more, continuous vibration can lead to internal damage. Over time, these small issues can cause complete failure. If your generator starts sounding different, have it checked by a technician. It's always better to catch the problem early than wait for a full system failure.

2. Inconsistent Power Output

An aircraft’s generator should deliver stable electrical output. If power levels suddenly drop or fluctuate, there’s a clear issue. This may be due to worn brushes, damaged wiring, or faulty voltage regulators. Moreover, fluctuating power can affect the performance of essential systems like lights, radios, and flight instruments. Inconsistent output isn’t just a nuisance—it’s a safety risk. If your systems are losing power unexpectedly, have the generator tested immediately.

3. Overheating or Smell of Burning

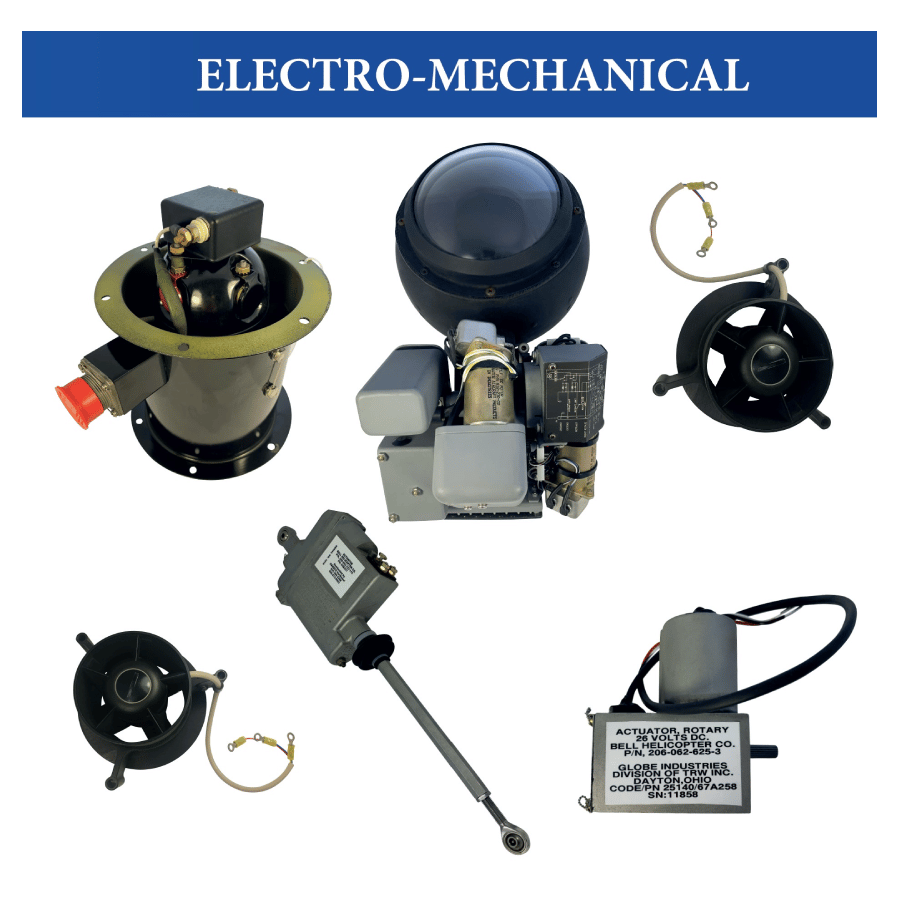

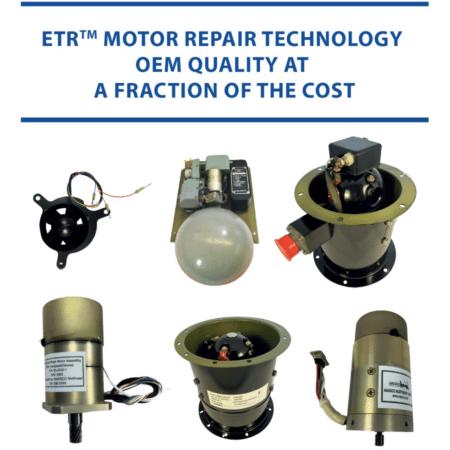

Overheating is a major red flag. If you notice that the generator is too hot or emits a burning smell, stop using it. Overheating can damage internal electromechanical component parts like windings or diodes. This often results from overuse, poor ventilation, or short circuits. The smell of burning is usually caused by melted insulation or wiring. Again, this is not something to take lightly. Prompt action can help prevent further damage and possible fire hazards.

4. Frequent Circuit Breaker Trips or Electrical System Malfunctions

If your aircraft's circuit breakers trip often, your generator might be the culprit. Faulty generators can send irregular power surges that trip safety systems. Equally important, this may indicate deeper electrical issues that need expert diagnosis. Frequent resets are not a fix—they’re a warning. Ignoring them can lead to serious electrical failure mid-flight. If you notice repeated tripping or random system failures, get the generator inspected right away.

5. Visible Wear, Corrosion, or Leaks

A visual inspection can reveal a lot. Check for signs like rust, oil leaks, or cracked components around the aircraft generator. Corrosion can weaken structural integrity and affect performance. Furthermore, oil leaks may signal seal failure or internal damage. These signs are easy to miss but should not be overlooked. Regular inspections can catch problems early. If you spot any of these visual cues, contact a certified repair shop for a full checkup.

6. Failing Performance During Functional Testing

Routine tests help ensure all aircraft systems are working properly. If your aircraft electrical generator fails during testing, it’s a serious concern. Maybe the voltage output is too low or it doesn’t hold a load. Such failures can indicate worn brushes, bad windings, or regulator issues. Functional tests are designed to catch these problems early. Lastly, if your generator can’t pass the test, it’s time to consider repair or even replacement.

Conclusion

Aircraft electrical generators play a vital role in flight safety and system reliability. When it starts showing signs of trouble, immediate action is necessary. Unusual noises, fluctuating power, and overheating are not problems to ignore. Frequent electrical faults and visual damage are also major warnings. Finally, failing test results mean the unit may no longer be safe to use. Staying alert to these signs helps avoid costly downtime and serious in-flight risks.

Need help with your aircraft’s electrical generator? Let NAASCO’s trusted experts take a look. Get in touch!

Write a comment ...