Aircraft operations are complex, with countless systems working in perfect harmony. Even minor component failures can lead to unexpected downtime and increased expenses. Maintaining electro-mechanical components efficiently is key to keeping fleets reliable while controlling costs.

Cost-Saving Maintenance Strategies That Keep Your Aircraft Running Smoothly

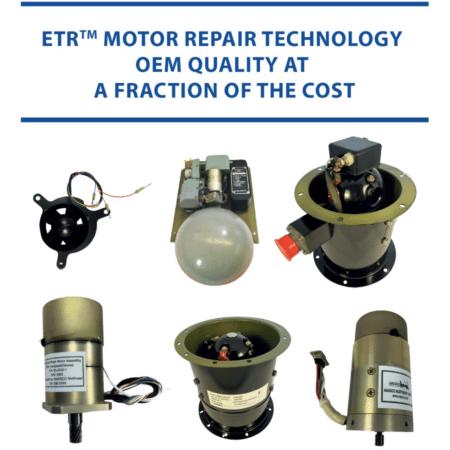

1. Starter Generators and Motors: Timely repair and overhaul prevent costly replacements and ensure seamless power system performance.

2. Relays, Contactors, and Terminal Blocks: Advanced solutions like Sil-Met extend component lifespan, reducing the need for frequent replacements.

3. Landing Lights and Fan Motors: Repairs restore functionality, improving safety and operational efficiency without breaking the budget.

4. FAA/EASA-Approved Repairs: Regulatory-certified solutions guarantee compliance while avoiding unnecessary expenses.

5. Rapid Turnaround and Testing: Quick, precise repairs minimize downtime, keeping aircraft operational and reducing revenue losses.

Proactive maintenance of electro-mechanical components is more than a technical necessity, it’s a cost-saving strategy that enhances fleet performance and reliability.

Maximize your fleet’s reliability while minimizing costs, trust NAASCO for expert electro-mechanical component maintenance. Submit your RFQ or download our brochure now to get started!

Write a comment ...