Landing lights are more than just compliance equipment—they're safety essentials, especially during low-visibility operations, nighttime flights, or rough weather conditions. For Cessna twin turboprop aircraft, the Honeywell Landing Light Motor ensures dependable deployment and retraction of landing lights, making it a vital part of the lighting system.

The Role of the Honeywell Landing Light Motor

Installed in aircraft models like the Cessna 425 Conquest I and 441 Conquest II, the Honeywell Landing Light Motor is designed for smooth, consistent movement of exterior landing lights. This motion is critical—not just for visibility, but also to protect the light fixture when not in use and reduce aerodynamic drag.

Over time, exposure to temperature fluctuations, moisture, vibration, and regular cycling can cause the motor’s internal components to wear down. Signs of trouble may include delayed light deployment, uneven movement, or total system failure. In some cases, pilots might only notice an issue during a critical moment on final approach—a scenario no operator wants.

Common Issues to Watch For

Motor fatigue due to overuse or corrosion

Electrical failures in wiring or connection terminals

Gear wear affecting speed or movement precision

Inconsistent retraction, causing lights to remain partially exposed

Proactive maintenance and timely repair are key to avoiding in-flight surprises. Routine inspections during scheduled maintenance cycles can detect these issues early, preventing costly AOG events or safety risks.

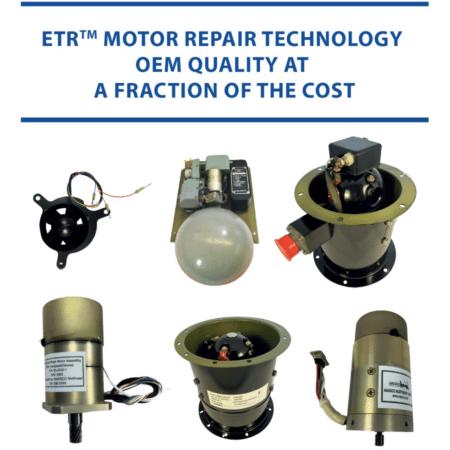

Precision Repair Matters

While full replacement of a Honeywell Landing Light Motor can be expensive and time-consuming, certified repair services provide a more efficient option. FAA- and EASA-approved technicians can disassemble, clean, repair, and fully bench-test these motors to restore OEM-level performance. For fleet operators, this approach offers consistency, reduced costs, and faster turnaround.

Honeywell Landing Light Motor repair isn’t just about fixing a part—it’s about preserving mission readiness, extending component life, and ensuring your aircraft stays safe and visible in all conditions.

Write a comment ...