In the fast-paced aviation industry, keeping fleets efficient and airworthy is a top priority. Operators face constant pressure to reduce downtime, manage costs, and maintain reliability. Aircraft Motor Repair Solutions are now revolutionizing maintenance practices by offering smarter, more affordable ways to keep essential components performing at their best.

Modern repair technologies have reshaped how airlines and MROs handle motor maintenance. Here’s how Aircraft Motor Repair Solutions are making a difference:

1. Cost Savings Without Compromise

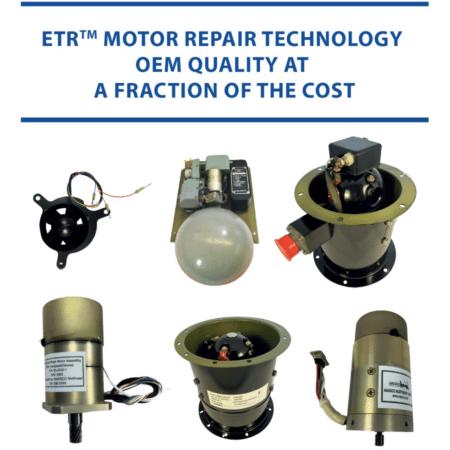

Certified repairs restore motors to OEM-quality standards at a fraction of replacement costs, helping operators save significantly on maintenance budgets.

2. Longer Component Life

Innovative processes like NAASCO’s ETR™ (Electro-Technology Repair), extend the service life of aircraft motors, minimizing the need for frequent replacements.

3. Faster Turnaround Times

With efficient repair methods, aircraft experience less downtime, keeping fleets operational and reducing schedule disruptions

4. Compliance and Safety Assured

All repairs are FAA/EASA approved, ensuring adherence to stringent aviation safety and quality standards.

5. Sustainable and Eco-Friendly

Repairing instead of replacing motors reduces material waste, supporting greener maintenance operations across the aviation industry.

6. Versatile Applications

From landing lights and blowers to windshield wipers and actuators, Aircraft Motor Repair Solutions cover a wide range of AC/DC motor systems.

Aircraft Motor Repair Solutions are transforming fleet maintenance by combining reliability, affordability, and sustainability, helping operators achieve peak performance and long-term value.

Since 1984, NAASCO has been a trusted name in Aircraft Motor Repair Solutions, offering FAA/EASA-approved repairs backed by innovation and proven expertise. Contact us today!

Write a comment ...